Slide Gates are used to control the discharge of bulk materials from hoppers, bins, silos or conveyors. Slide Gates consist of a rigid frame with a slide plate located inside that opens and closes against the flow of material. The slide plate can be actuated by hydraulic means.

The slide plate is supported by frictionless rollers to allow for easy actuation. The slide gate assembly utilizes bolted covers on both the top and bottom to create a dust-tight enclosure while allowing easy access for maintenance. Our slide Gates are a great complement to our bulk material handling and processing equipment.

• Located at intermediate discharge points on conveyors for evenly loading trucks

• Located at the discharge of a silo to cut-off the flow of bulk materials to a feeder

Our Slide Gates make plant layout much more efficient. Intermediate discharge points with slide gates can be added to a conveyor so several different process lines can be fed with bulk materials by opening and closing Our Slide Gates as required.

Our Slide Gates are custom designed for your application based on proven design standards. Bulk materials ranging from free-flowing cement to sluggish dewatered bio-solids can be controlled using Slide Gates

Our slide gates are typically used under the discharge of:

• Screw conveyors

• Drag conveyors

• Belt conveyors

• Hoppers

• Silos

• Mixers

• Other special process equipment

We can provide slide gates with prefabricated insulated air conditioner cabins with control panel. We have already provided these types of gates.

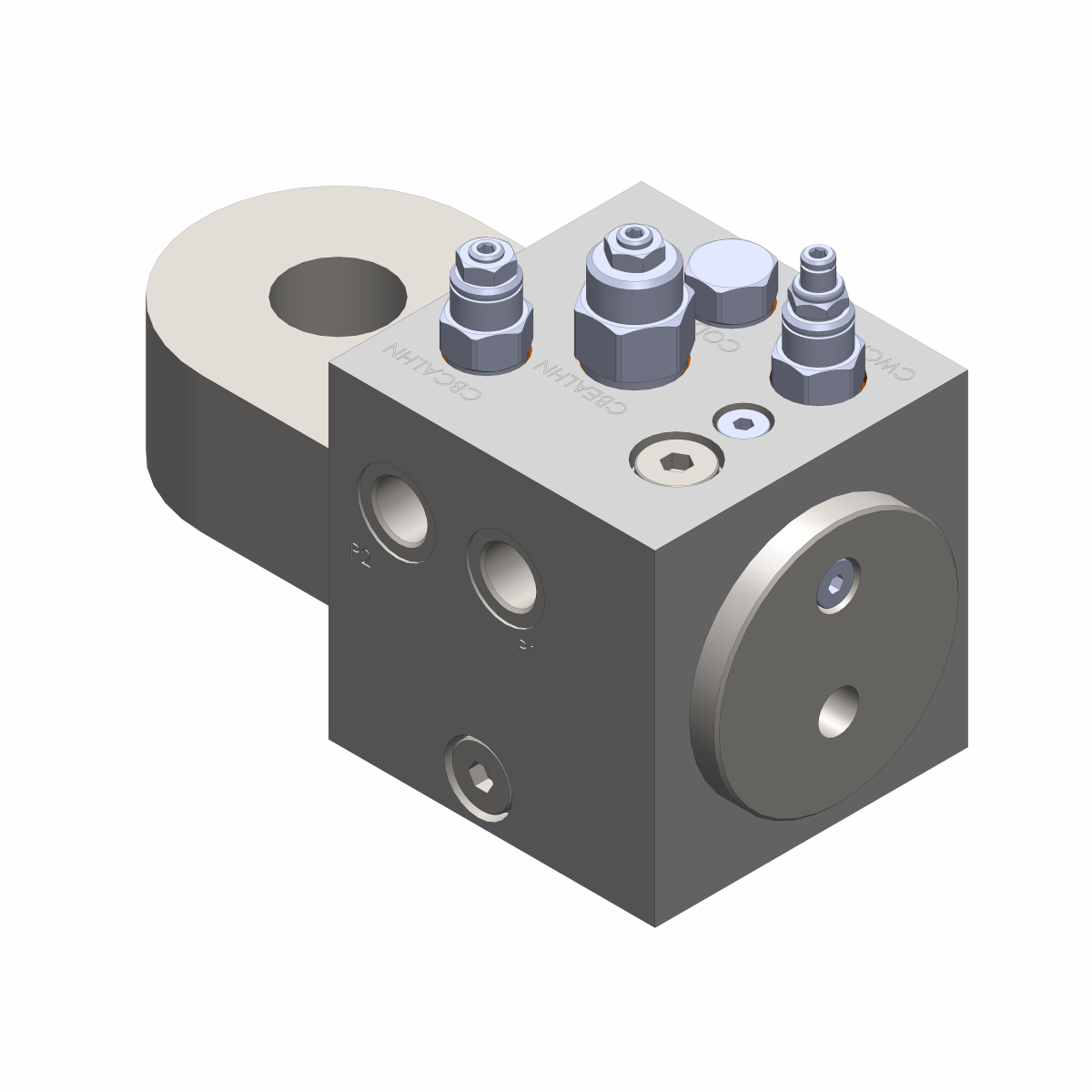

| 1. Piston Rod: High strength alloy steel piston rods toughened, accurately ground & hard chrome plated to ensure anti-corrosion and maximum life of seals. |

| 2. Barrel: Seamless Drawn cylinder pipes are precisely honed to a fine finish internally to provide long life for piston seals & to prevent corrosion. |

| 3. Piston & Head: High strength alloy steel is used to make Piston, Head, Backend etc. These are accurately machined on atomized machine to get highly perfect size & better finish. |

| 4. Seal kit set: We are using imported best quality seal kit sets of different materials as per requirements. |

| 5. Mountings: We offer wide varieties of mounting styles to suit all user requirements. |

| 6. We offer optional piston rod threads on request |

| 7. Inspection: We are using best quality material to manufacture the cylinder & can be inspect each and every material as well as process parts for its different parameters & allowable tolerances. We perform hydrostatic pressure testing of all hydraulic cylinders at maximum working pressure for leakage & guaranteed performance. |