We manufacture wide range of Hydraulic operated presses for various applications. Our presses are precisely fabricated & machined for its optimum performance at low maintenance cost.

Frame is fabricated from prime steel plates of proper thickness for greater strength & rigidity. All frame is designed on latest softwares to resist any deflection & capable enough to withstand high pressure & vibration damping capabilities.

Different kind of guiding arrangement are provided to suit the application of the press long guiding length & suitable guide with centralized lubrication system is provided in the presses.

The function of the draw cushion is to hold the blank during deep drawing operations. The cushion thus prevents the formation of wrinkles & as a result of the ejection function, raises the parts to the transport level or ejection level during the return motion of the slide. The cushion is designed for about 30% of the main ram tonnage when in cushion mode

Mechanical stoppers are provided as a safety feature to limit the maximum stroke of the main ram after pressing, to protect the tool from damage.

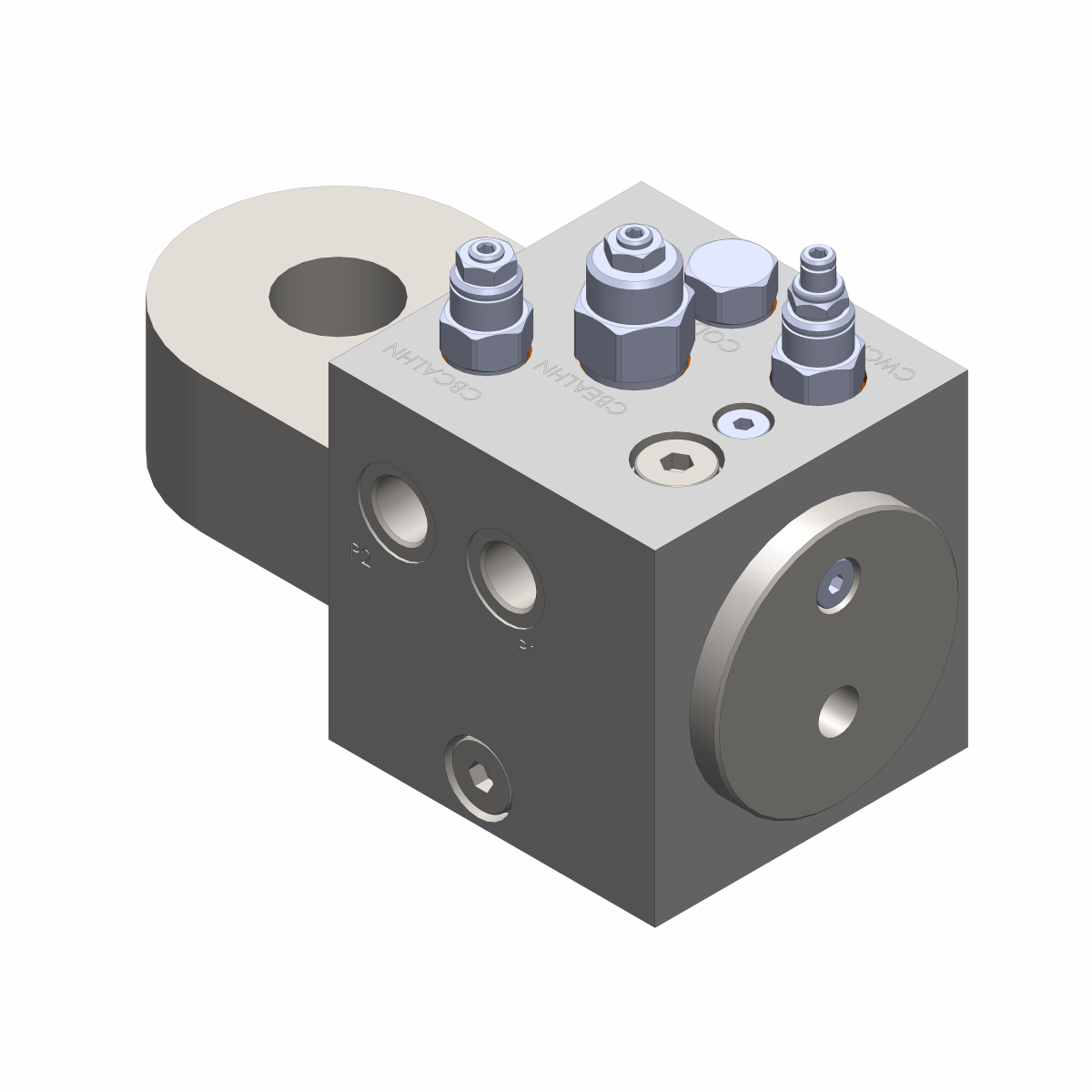

'JAGDAMBA' hydraulic system is most reliable & the backbone of hydraulic presses. It involves a compact manifold Block to avoid piping thus less chance of any leakages in the system so pressure will remain constant throughout the cycle. All the valves are internationally reputed make, so reliability is more. High quality indigenously made precision hydraulic cylinders with low friction PTFE seals with 60%. Bronze guide tapes ensure operation & long life of the press.

The press controls are designed into a panel which is mounted at type level on the press. It has user friendly controls & has safety features to protect the operator from accident. The control has manual / semiauto / Full auto functions. Top cylinder is having proximity sensors to set the required stroke

Ram slides / guides/ guide bushes are lubricated from a centralized lubrication arrangement.

It is a fabricated, heavy duty, tested welded plate construction for highest stiffness under heavy loads. The whole platen is stress-relieved after welding. 'T' slots provided in the platen are as per DIN standards. Hydraulic or mechanical ejector pins to operate from inside the ram is also provided as optional on request or depending on the application.

Applications

| • Work Shop Press |

| • Scrape Bailing Press (Metal/PIastic/ Paper) |

| • Deep Draw Pressrs |

| • Special Purpose Press |

| • Sheet Metal Press |

| • Stamping Press |

| • Lamination Press. |

| Characteristics | Hydraulic Presses | Mechanical Presses |

|---|---|---|

| Force | Relatively constant (does not depend upon slide position) | Variable (depends upon slide position) |

| Stroke Length | Capable of long stroke 100" (2540 mm) or more | Very limited |

| Capacity | 50,000 tones or more | About 600 tons maximum practical |

| Wear & Tear | Very Less | Very High |

| Maintenance Cost | Very Less | Very High |

| Rejection Chemicals | Very Few | Very High |

| Final Product Quality | Best | Good |

| 1. These presses provide fast approach slow pressing & fast return speeds. The change in speed can be manually preset to take place at any point of the stroke with the help of limit switches / proximity switches. |

| 2. The frame is fabricated by ultrasonically tested quality profiles & plates of suitable thickness to with stand the load & longer life of the press. |

| 3. Maximum frame rigidity is achieved through computer aided frame design & finite element analysis. |

| 4. Extra long, precision machined & hardened guides to face slides offer exceptional accuracy & alignment which further reduced to wear. |

| 5. In blanking or punching, hydraulic presses a damping system can be fitted. This effectively reduces breakthrough noise & tool wear normally generated by such operations. |

| 6. The low noise hydraulic power pack unit is designed as per international practices & assembled with internationally reputed make components. The presses are designed as per ISI guidelines, hence standard seals, bushes are used. |

| 7. Precise machining of the structural members is done after normalizing to get the required accuracies like parallelism between platen & bed & right angularity between bed & the moving platen. |

We offer heavy duty tie rod type type hydraulic deep drawing presses, which are widely used in different industries to manufacture deep drawing components. These are heavy duty, high performance & durability. All the presses are impeccably equipped with most advanced hydraulic & electronic controls. They are designed for high off center loads with heavy RAM force. Accurate slide guiding with full stroke length is helpful to provide the better accuracy & effective performance of the presses. Deep draw press is perfect for deep drawing automobile sheet metal components, oil tanks, stainless steel kitchen sinks, mudguards etc. It has capacity to draw all the draw able materials. Apart for our standard models we can build machine as per your requirement.

Sizes: from 20 – 1000 Ton

Circle size: from 100 mm to 2000 mm

Max deep: As per customer requirement

Control : Manual / electrical panel

All the presses is having T slot at top plate for easy die holding

| Standard Models | Capacity (Tons) | Max Circle to Draw | Max Draw Deep | Electric Motor H.P |

|---|---|---|---|---|

| JAG-35 | 35 | 14" | 5" | 5 HP |

| JAG-45 | 45 | 14" | 5" | 7.5 HP |

| JAG-60 | 60 | 20" | 8" | 10 HP |

| JAG-90 | 90 | 24" | 10" | 10/15 HP |

| JAG-110 | 110 | 28" | 12" | 15 HP |

| JAG-165 | 165 | 32" | 13" | 15/20 HP |

| JAG-210 | 210 | 40" | 14" | 20/25 HP |

'H' TYPE or Fabricated 4-column Type

Jagdamba 'H' TYPE or Fabricated 4-column type hydraulic presses are heavy duty and their frame is manufactured using ultrasonically tested quality plates of suitable thickness. These presses find extensive application in deep drawing compression moulding.

'C' Frame Type Presses

'C' Frame Type Power Press is configured with the use of latest technology. These optimally functional presses are simple to install and requires minimum maintenance. They can be customized as per the specific needs of the customers.

4-nos Hard Chrome Pillars Type Presses

Jagdamba offers 4-nos Hard Chrome Pillars Type Presses in different technical specifications. The guide of this type of press offers excellent slide accuracy of the moving ram and the platen, resulting in reduced tool wear and an increased service life.

TYPE: Tie rod construction, H type, C type.

Sizes: from 30 – 1000 Ton

Table Size: As per customer requirement

Control : Manual / electrical panel