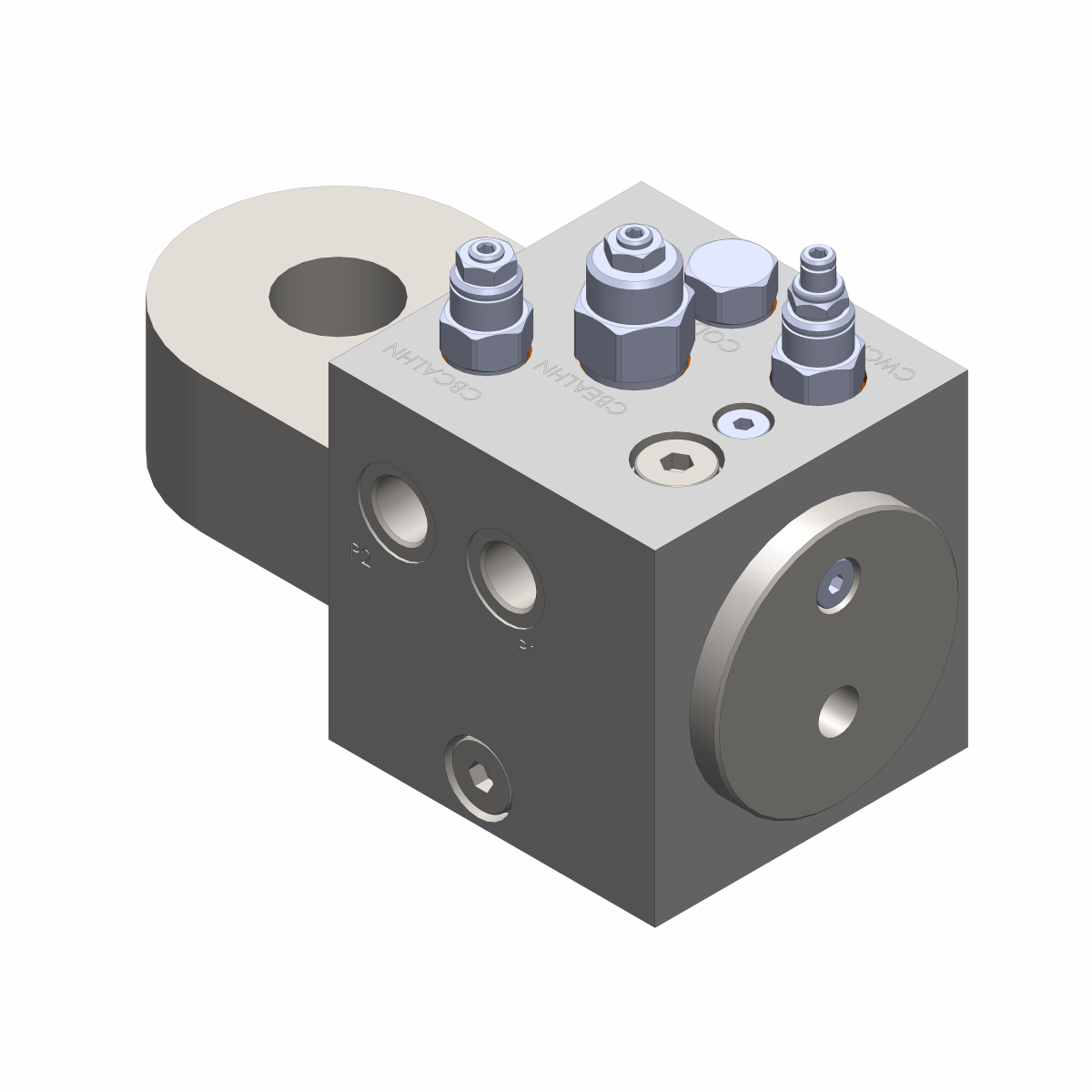

We specialize in hydraulic cylinder repair, reconditioning, overhaul, and testing. We thoroughly evaluate and analyze every aspect of the cylinder, including the barrel, piston, rings, seals, and rods using our state-of-the-art equipment and testing methods. With our in-depth diagnostics and hydraulic cylinder inspection techniques, we detect all possible defects and modes of failure and perform the appropriate repair or maintenance procedure. Decades of experience, combined with our cutting-edge tools and services, allow us to repair hydraulic cylinders with greater efficiency, which translates to superior cylinder performance and reliability. Some of the evaluation and repair capabilities include:

• General life-cycle hydraulic cylinder maintenance

• Industrialized disassembly, reassembly, and full hydraulic testing

• Regulatory cylinder inspections

• Complete cylinder reconditioning

• Complete pressure testing to check real working conditions

• Retrofits and valve overhauls

• Resealing and main relief setting

• Tube honing

• Custom welding

• Isolated valve change-outs and resealing

• Rod resurfacing and scratch removal

• Lapping for thrust and valve plates

• Crack repair

• Barrel replacement

Hydraulic cylinders are available in many unique sizes and configurations depending on their application. We have versatile range of industry-leading hydraulic cylinder repair can meet the needs of many industries, including power plants, utensils, auto components, sheet metal, automotive, construction, steel, cement and transportation industries. We also thoroughly test all our repairs to make sure they satisfy every specification.

We specializes in hydraulic cylinder repair services for the following industries:

• Power Plant

• Cement Plants

• Steel Plants

• Utensil Manufacturing

• Construction

• Automotive

• Metal fabrication

• Railroads and rail transportation

• Manufacturing

• Agriculture

• Aerospace