If you’ve ever wondered exactly how hydraulic manifold repair is done, here are the steps we take. We like to think we’re a bit more efficient than other hydraulic maintenance companies when it comes to hydraulic manifold repair, something we’re quite proud of. Here’s how it works:

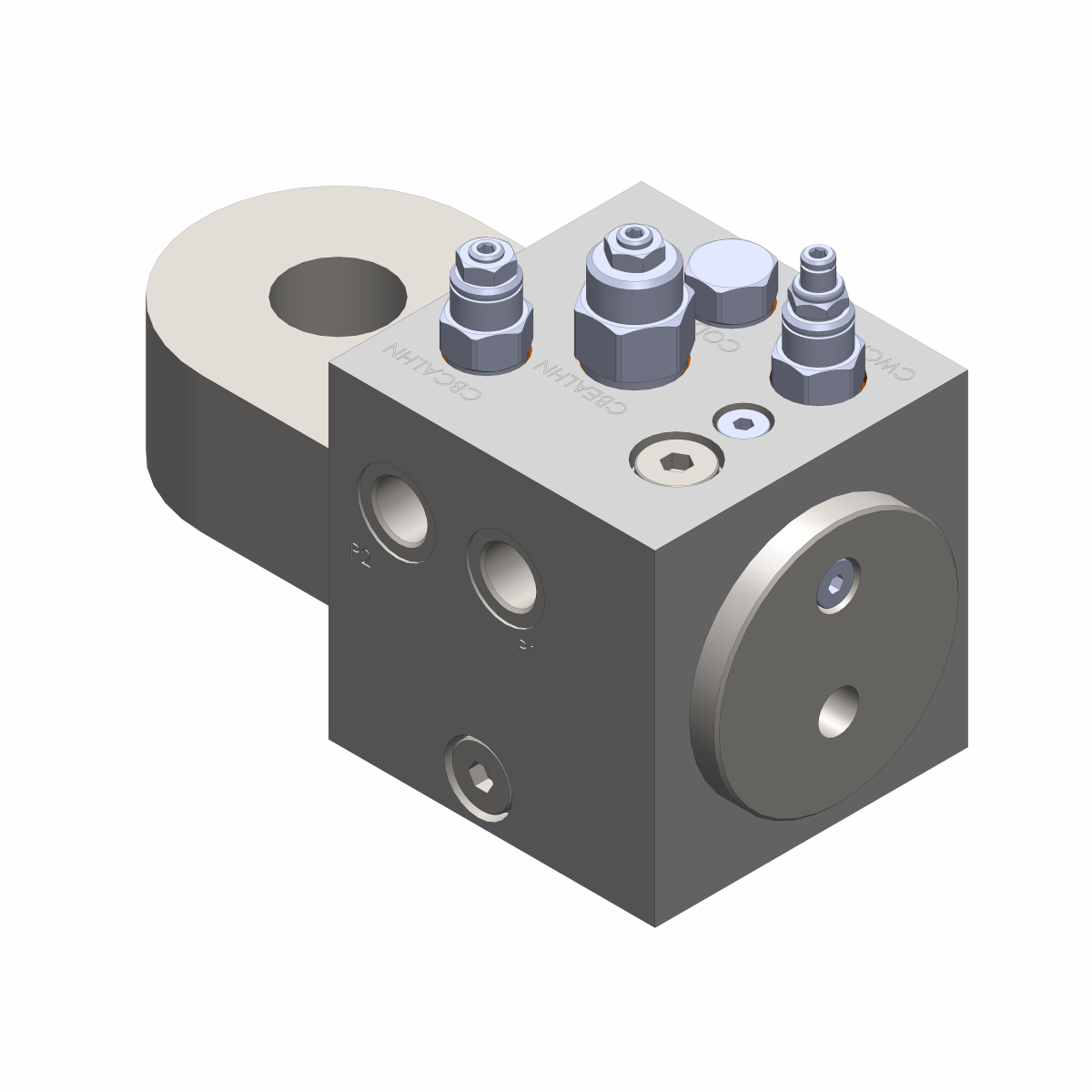

1. Determine the Valve Type – When we find your hydraulic manifold problem, your manifold comes to us for repair under the auspices of a master hydraulic mechanic with years or even decades of experience. When we receive your manifold, the first thing we have to do is determine what kind of manifold it is. A hydraulic manifold is a very broad term, and we could be dealing with everything from a small manifold to a much more complex manifold. We’re equipped to handle any type of hydraulic manifold, but the type it is will play a factor in the approach we take to repairing your Manifold.

2. Disassemble the Valve – Once we know what we’re dealing with, Our technicians look for any kind of defect, wear or other issues that could be responsible for the manifold failure. We scrutinize all aspects of the valve carefully so that we can detect any possible problem, from a leaky O-ring to some kind of contamination affecting the spool.

3. Test the Systems to Find the Source of the Problem – Once that’s done, it’s ready to go to electrical where we put it back together and start testing the systems electronically to locate the source of the problem. How long it takes to break down the manifold will depend on the complexity of the it, but we take as long as is required to systematically separate every piece of the assembly that could potentially have a problem with it. We leave no stone unturned in determining the source of your manifold problem. If everything looks good, we’ll try replacing the soft seals, which is the next likely source of the problem. We do this in a clean room or area to avoid contamination. You can be sure if there’s anything that moves or can be removed in the Manifold, we will take it apart and inspect it for wear or damage. We will replace the seals, valves, fittings and anything else that needs replacing to make sure the valve meets OEM specifications.

4. Reassemble and Conduct Final Testing – Once we’ve located all the issues, replaced any necessary worn out parts, valves & seals and tuned up the electronics, we’ll put it all back together and mount it onto our sophisticated testing equipment where we’ll verify that everything is operating according to OEM standards..